Welding supplies can really burn a hole in your pocket, right? No matter how much you try to save your precious money, you can’t avoid having to fork out the cash on new equipment and supplies.

After all, one must have the necessary machinery and tools to get the job done. However, it’s not all doom and gloom. There are things that you can save some money on if you are willing to put in some effort.

Welding cable reels are one such thing. Instead of buying the industrial ones, you can make a homemade one without having to spend exorbitant amounts of money.

What are Welding Cable Reels?

Welding cable reels are priceless to welders. Even newbies just starting out with their own welding rig trucks are encouraged to get themselves some reels.

Welders usually have to work with lengths and lengths of welding cables that can be very hard to store and keep track of. A welding cable reel helps to keep the cables organized and in good shape, which also makes life easier for the welder as their shop remains organized and uncluttered.

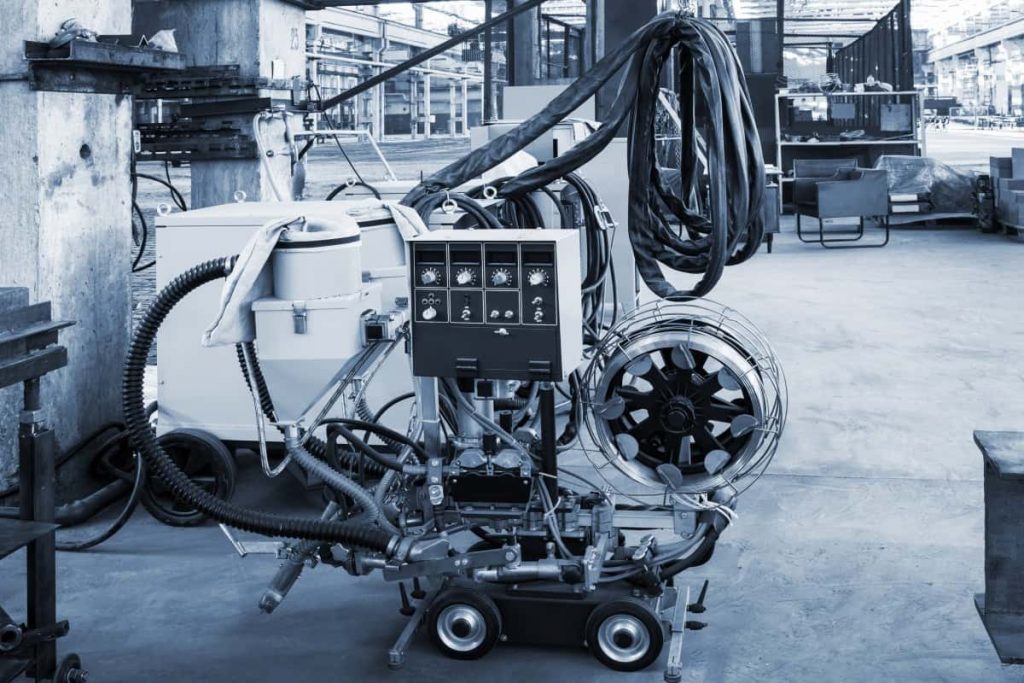

Welding cable reels are large, drum-shaped, objects like a spool. They are used to store electrical cables, fiber optic cables, and all sorts of wiring. They make the storage and transportation process super convenient and also helps keep the cables in good shape, as the cables are less prone to being damaged when they’re properly coiled up on a reel.

Welding cables are loose cables sold in lengths starting from 25 feet, going up to however much you require. Carrying and storing such large reels is not only difficult but also naïve. The reels are bulky and need to be made from a material that can hold the reel for safe and efficient storage and allow for effortless transportation, without damaging the cables or comprising on the quality of the work.

What Are the Advantages of Using Welding Cable Reels?

Cable reels don’t just make your life easier; they also save you money, time and unnecessary hassle. When cable reels that long are left strewn around, they can cause a lot of damage to the people around and can sustain damage themselves.

Trip Hazard

Imagine a large cable reel snaking around the floor of a workshop. Welders who are working within the small space, wearing protective gear and welding masks are at risk of getting their foot tangled in the wires. Once this happens, they’re inevitably going to and trip and fall.

Given the dangerous work environment and the tools they are working with, the situation can get really messy. Such long cords should not be left around like that, and coiling them by hand might not be the best practical solution, as they could come loose again. You have to find a way to keep them in one place, preferably somewhere that they can’t come loose from

Maximize the Life of Welding Cables

All of a welder’s equipment is pretty pricey, and welding cables are no exception. When you invest in good-quality welding cables, you want them to last for a very long time. To make anything last longer, you have to keep it carefully handled, safely stored, and well-maintained. To ensure that your cables have a longer life, you need to find a home where they are safe and free from harm when not in use. Cable reels ensure that your cables are stored properly without being twisted or stressed. They are also at no risk of tearing and fraying when they are not getting under anybody’s foot, are not left hanging around sharp objects, and are not in a compromised position when traveling in the back of your truck.

Convenience

This one is obvious. Having a cable reel makes the storage and transportation of the cables seem like a breeze. The cable reel can then sit in your workshop, or travel on your welding rig truck, safely tucked away, as it should be.

What Do You Need to Make Your Own Welding Reel?

If you plan to make your own welding reel instead of getting one from the market, you will need the following supplies.

- 2 identical shaped, metal/wooden plates

- A sturdy rod or piece of metal or wood to wrap the reel around

- Drill machines, nuts, bolts,

- Hand crank (if required)

While it will take some effort, you will end up saving a lot of money, and for rookie welders, homemade cable reels will do just fine.

How to Make Your Own Welding Cable Reel

If you don’t have the finances right now to buy secondary equipment like welding cable reels, you do not have to do so. Welding equipment is very expensive, and you can always get a cable reel later. You can simply make a homemade version for yourself at this point and get an industrial one later if the need arises.

Here is a step-by-step guide on how to make a welding cable reel:

- Take a steel 1/4-inch steel plate, which will form the base of the welding cable reel.

- Drills holes that are approximately the same size and diameter as the anchor bolts you’re using. Space these holes about one inch from each of the corners.

- Take another identical steel plate and do the same with it.

- Place and fix the rod in between the two 1/4-inch, drilled steel plates. Then, weld it in place. The welding cable reel post has now been fixed.

- Now, tip this pose to one side. It should be resting on the edge and the top part of the steel base.

- Weld the post and the rim together after positioning the rim in the desired position on the post.

- Make the welding cable reel stand straight and admire your work.

Your homemade welding cable reel is ready. It can hold and transport your cables with ease and convenience. It might not be as fancy as the industrial ones, but it will serve you well for the time being.

Limitations of Homemade Cable Reels

Homemade cable reels are great for beginners who are just starting out with their own welding rigs, but how do they compare with industrial mobile cable reels? Are the homemade reels safe enough? How long do they last, and how sturdy are they? Should we be encouraging beginners to invest in a good industrial cable reel too?

While the homemade cable reels will serve you well, when you’re starting out and don’t have to keep huge stocks of welding cables, and do not have to haul cables too far, then you don’t need to buy industrial cable reels. However, when your business starts expanding, you might need to make the switch to electric, industrial welding cable reels. Some of the limitations of homemade cable reels are:

- Most homemade welding cable reels are manual. When you have bigger clients and projects, manually reeling in the cables might not be the best choice.

- They might not be as sturdy as industrial ones. Some of them may be made out of wood and might not be able to withstand large loads that you might have to carry on bigger welding projects.

- You might hurt yourself while handling these cables and reels manually. Industrial reels have a lot of safety and protective attachments to avoid accidents.

How much would it cost you to make a welding cable reel at home?

The cost of a homemade welding cable reel will vary from place to place and depends on the quality of the material used. But it’s safe to say that you can make a good welding cable reel in half the price of an industrial one.

How much does a ready-made cable reel cost?

A good quality, branded cable reel off the market would approximately cost you $300.

What is preferable: manual or automatic reel retraction?

Manual reel retraction, which is what most homemade cable reels would offer, is a lot of work. The cables can extend up to 50m, and manual retraction can be time and energy-consuming.

Automatic reel retraction will help you save time and energy, but at the same time, it sometimes poses a danger to the person operating it if it retracts too fast.

What are the types of cable reels available in the market?

Here are some of the welding cable reel options you will have in the market:

• Spring Driven Reels: Automatic reels that retract the reel themselves when you let go.

• EZ Coil Reel: Reels that retract slowly for the safety of the operator.

• Hand Crank Reels: Comes with a hand crank that you have to rotate to bring the reel back. It requires a lot of manual power.

• Motorized Reels: Reels that require a power source and rotate to retract the reels themselves.