Although seal welds may not serve structural purposes, they are nevertheless important. Not giving due regard to seal welds can create several unexpected key issues during welding.

What is a seal weld? The main purpose of seal welds is to provide resistance against leakages. These welds prevent fluids (liquid or gaseous) from entering a cavity, which helps limit corrosion. Unlike exposed joints, seal welds make surface cleaning easier.

Read on to find out more about seal welds, the best practices concerning these joints, issues pertaining to seal welds, how these issues are resolved and possible conflicts that occur between design requirements and AWS welding provisions.

Purpose of seal welds

For structural and mechanical applications, a seal weld is used to prevent the inflow of fluid since it can cause harm, such as corrosion. In the aforementioned applications, seal welds are often not used to prevent fluid from leaking out of a container. In these scenarios, seal welds prevent the infiltration of oxygen-laden air and moisture, which can cause rusting, corrosion and other damages.

Parts that must be galvanized are often specified with seal welds to prevent liquid zinc and pickling acids from going inside a certain space. Seal welds are applied on exposed steel columns that are to be painted to stop rust bleeding. These welds are also used for those applications where it is easier to clean a sealed joint rather than an exposed joint. An example of this is food processing facilities.

The aforementioned applications have one characteristic in common. Seal welds are not used for strength purposes. For this reason, you should exercise caution wherever seal welds must be used. In certain cases, the seal weld application can lead to a clash between code requirements. For other cases, seal welds may unintentionally perform structural functions. This can result in undesirable load paths. Seal welds may have an effect on inspection, particularly ultrasonic inspection results.

Finally, welding operators may treat seal welds casually. This may result in weld quality issues.

Weld seal code conflicts

One common inquiry is that for drawings that specify seal welds, the requirement cannot be fulfilled unless AWS D1.1-98, Section 2.4.7.5 is violated.

The code section involved in this query is one that requires weld interruptions for opposite sides in a single plane. For such a situation, the welds must be interrupted at a corner.

This provision has an important practical purpose. Making a continuous weld under such circumstances is difficult. If the welds are continuous, then there is a high likelihood of undercutting corners. This is an issue that arises when seal welds must be created in such situations.

There are also other codes that may possibly be violated. An example of this is the AWS D1.1, Section 2.4.7.3, which is concerned with flexible connections that depend on the outstanding leg flexibility in angles. For instance, this can include end plate connections, top angles in seated bean connections and framing angles. You may reduce this flexibility by applying seal welds around these flexible connections.

According to the AWS D1.1, Section 2.4.7.4, stiffener welds should not be cut short under four times or more than six times. This provision was included so that there may be some amount of flexibility within the region. It was noted in shipping applications that this region has a tendency to crack if the weld was applied too far. Seal welds are applied to this region to prevent such flexibility.

A designer who requires seal welds should peruse the aforementioned provisions if the D1.1 is pertinent to the project. For applications where the code is not relevant, the designer should consider such principles to determine whether or not they are suitable for components where seal welds have been used.

In order to manage conformity between both code requirements and job specifications, the engineer can specify solutions so that these two requirements can be fulfilled without conflict.

Only a few examples have been mentioned where there is a possibility of conflict between job and code requirements. This is by no means a comprehensive list of examples. There are also other provisions, which may be violated.

Creation of alternate load paths

Other problems can arise when load paths are unintentionally created. For instance, bolts may join a lapped connection when no welds were expected. However, there may be a call for seal welds around this connection. You may apply AWS D1.1, Section 2.6.3 for such situations. For bearing connections, the provisions do not permit welds and bolts to share the load.

In these cases, the designer will certainly not want seal welds to share the load. In fact, it will happen albeit unintentionally. The seal welds may be comparatively small and not be capable of transmitting applied loads on their own. As a consequence, the welds may fracture during service. This will violate the purpose of seal welds. The bolts may then carry transferred forces as a result of loading up.

While considering seal welds, you should pay attention to the principle according to which welding design has no secondary members. An example of this is a tub-type rock crusher that was designed with an array of stiffeners. The details were carefully worked out to prevent stress risers. A stainless steel nameplate was attached to this unit for which seal welds were required. Multi-coat paint was applied to the entire unit to prevent corrosion.

Seal welds were applied to ensure that the region underneath the stainless steel plate did not come in contact with the elements. The plate was located within a high stress region. As a result, it was included unintentionally in the load bearing arrangement. The welds, themselves, introduced residual stresses.

The seal weld created for the nameplate turned into a design issue where crack initiation was noted during service. The aim of the design was defeated due to the location of the seal welds. For this example, any other weld besides seal welds would also have led to poor fatigue characteristics.

Lax attitude towards seal welds

The creation of seal welds may also violate the minimum heat limit as per AWS D1.1. Table 5.8 within this provision recommends minimum weld sizes, irrespective of the amount of the load. This recommendation ensures sufficient heat input during welding. The seal weld size may not be mentioned. This may result in a weld that table 5.8 may not allow. Still, it is crucial to follow good welding practices while making seal welds. This includes meeting the minimum size for fillet welds. Failure to follow this principle may cause incomplete fusion defects or weld cracking.

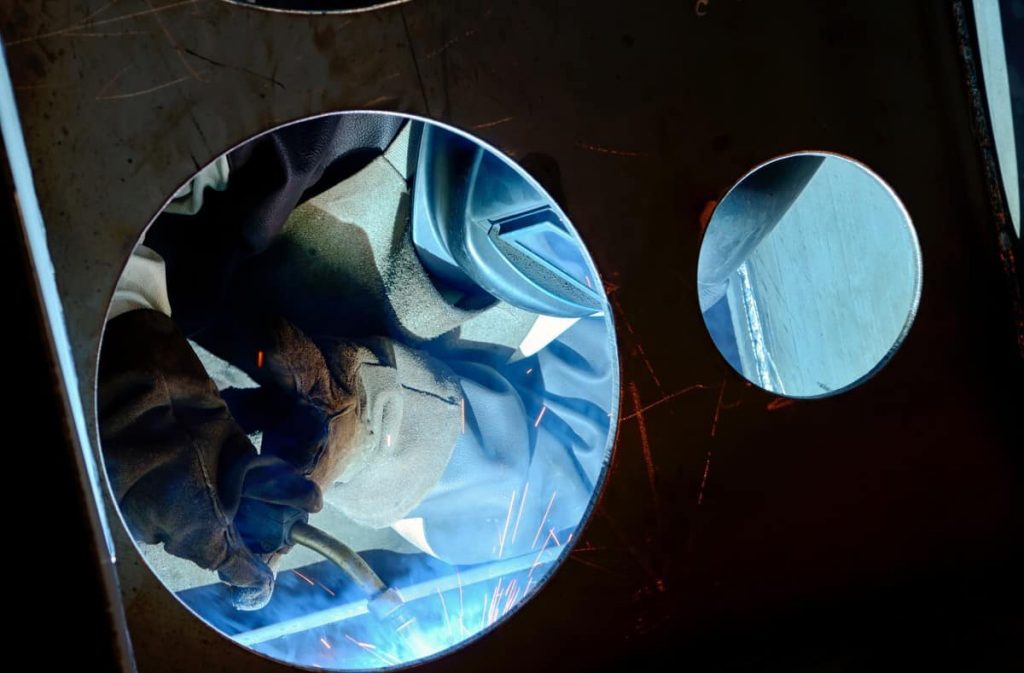

The welder in charge of this job may approach this situation casually. There is also a chance that the welding supervisor may have the same attitude. The welder must have the same qualification as an operator who makes welds for structural purposes. Seal welds require the same amount of attention to welding details (like the required preheat input and electrode selection and other factors) as does weld that transfers loads. A lax attitude towards seal welds can lead to an array of welding issues.

Inspection problems with seal welds

Seal welds present steel backing left after the completion of welding may have consequences when ultrasonic testing is performed for such connections. Consider a case where the CJP groove weld around steel backing must be inspected by ultrasonic testing. Seal welds are responsible for an alternate sound path. Such consequences should be given due regard prior to carrying out this inspection procedure.

If seal welding is done to join the backing with the base material, then you should consider the possibility of a wider backing. When the seal welds are moved away from the welded joint, there is a better chance that the ultrasonic waves will detect the root without any sending secondary waves passing via seal welds.

Galvanizing problems

Seal welds are applied in assemblies that must be hot dip galvanized. According to the American Galvanizers Association, there are 3 kinds of weld assemblies that are galvanized.

Class 1 joints must be joined with full seal welds. Class 2 joints must be held by seal welds. However, the overlapped area may be big enough to warrant venting. Escape holes are needed to release trapped gases. Class 3 joints lack seal welds.

If the overlapping area is in excess of 16 square inches, then a venting hole is required by AGA standards. Locations and diameters of these holes are also specified.