Before today, were you aware that high-frequency sounds can be utilized to bind together different materials? You most probably weren’t. Here is some information to add to your knowledge: Ultrasonic welding technology is used to combine items from a range of industries, including from the automotive, sports footwear, and medical equipment industries.

So, what is ultrasonic welding? It is a popular and widely used method for connecting thermoplastic materials. Several advantages are provided by this technique including efficiency and reproducibility of procedures, resource savings, and lower use of energy than other methods for joining. Here, we will discuss everything there is to know about ultrasonic welding.

What is Ultrasonic Welding?

Some of the common techniques we use to connect two materials are clamping, binding, and gluing. We can’t ignore the fact that welding produces the best outcomes though. Welds create solid connections that last much longer than most other joint types.

Today, there are various welding techniques in use. Every technique is specific in its way and is utilized according to the material type and specifications involved. Ultrasonic welding is amongst the most sophisticated welding techniques in use currently. It is used to tie together various items. A great benefit that you get with ultrasonic welding is that it can be utilized on non-metal materials, such as thermoplastics.

What is the Ultrasonic Welding Process?

In the plastics processing industry, the ultrasonic joining technology has been utilized in a wide range of applications as a joining tool for specialized thermoplastic materials. Ultrasonic welding has a fast and easy operation. This welding process can be performed in the following six simple steps.

Step 1—Nesting the Parts Together

The thermoplastic components that need to be erected are put together in a fixture, which is a supportive nest. They are placed one over the other.

Step 2—Bringing the Horn in Contact with the Plastic

The ultrasonic horn constructed of aluminum or titanium comes into contact with the top plastic component at the top. This is the same component that needs to be burned for making the connection.

Step 3—Applying Pressure

The components receive a controlled pressure, which fastens them with the fixture.

Step 4—Weld Time

The ultrasonic welding happens for the specified amount of time that the design requires. The horn is pulsed in a vertical position between 20 kHz and 40 kHz times per second, maintaining minimal contact with the burning plastic. The mechanical vibration generates a heat of friction strong enough to burn the plastic material and the plastic starts flowing in a semi-liquid environment. When the usable plastic joint is molecularly formed, the welding is halted, allowing the plastic to cool down.

Step 5—Hold Time

The force of fastening is sustained to enable the parts to connect as the melted plastic cools and strengthens over a predetermined period. This is called hold time. Hermetic sealing and enhanced joint strength can be accomplished by the application of greater force during holding time. This is achieved by applying dual pressure during hold time at different stages.

Step 6—Retracting Horn

This is the sixth and final step in the ultrasonic welding process. The force of fastening is reduced when the molten plastic is fully cooled and hardened. At the same time, the horn is withdrawn away from the welded assembly. You may detach the assembly from the fixture and start the cycle over for the next collection of parts.

Ultrasonic welding assembling plastic is a technique that requires very little energy and is simple, safe, reliable, and reproducible. Additionally, no additives, sealants, mechanical clamps, or other supplies are needed. Despite this, solid and tidy finished assemblies are achieved.

How Does Ultrasonic Bonding Work?

The very first thing that comes to mind when you think about joining two or more components together is a common screw or a mixture of bolts and nuts. Although this is easy to perform, it can add costs and complexity to a manufacturing process that might not be necessary. A simplified solution is provided by ultrasonic welding which minimizes cost and complexity while fulfilling the assembly’s reliability criteria.

Ultrasonic welding utilizes thermal stresses produced by mechanical movement of high frequency to melt plastics. The vibration is produced by converting electrical energy through an ultrasonic mechanical horn which uses the heat generated and friction to burn the plastics and form a mechanical molecular connection between the related components.

To join two components of thermoplastic, the properties must be chemically compatible. If that is not the case, there would be no molecular connection, even though the two materials can be melted together. For example, try welding polypropylene to polyethylene.

Although these semi-crystalline substances are similar in structure and share several physical properties, they are not chemically compatible, and so cannot be welded together. They can only weld to themselves or materials with similar chemical properties. The only way two thermoplastics with different chemical properties can be compatible is if their melting temperatures are below 40ºF, and they have an identical molecular structure.

What are the Different Parts of Ultrasonic Welding?

Knowing the different parts involved in the ultrasonic welding process is extremely important to perform this welding technique efficiently. Ultrasonic welding machines are designed to transform electricity efficiently to mechanical vibrations. They are equipped with a microprocessor that reads the conditions and then controls the heating accordingly. The following are some of the components that enable the ultrasonic machines.

Power Supply

A high-voltage supply of power is needed by the ultrasonic high-frequency welding system.

Transducer

The high-voltage current is utilized by the transducer and transformed into vibrations of high-frequency.

Booster

It functions like an amplifier. This means that high frequencies are taken by the booster and then made even more efficient.

Horn

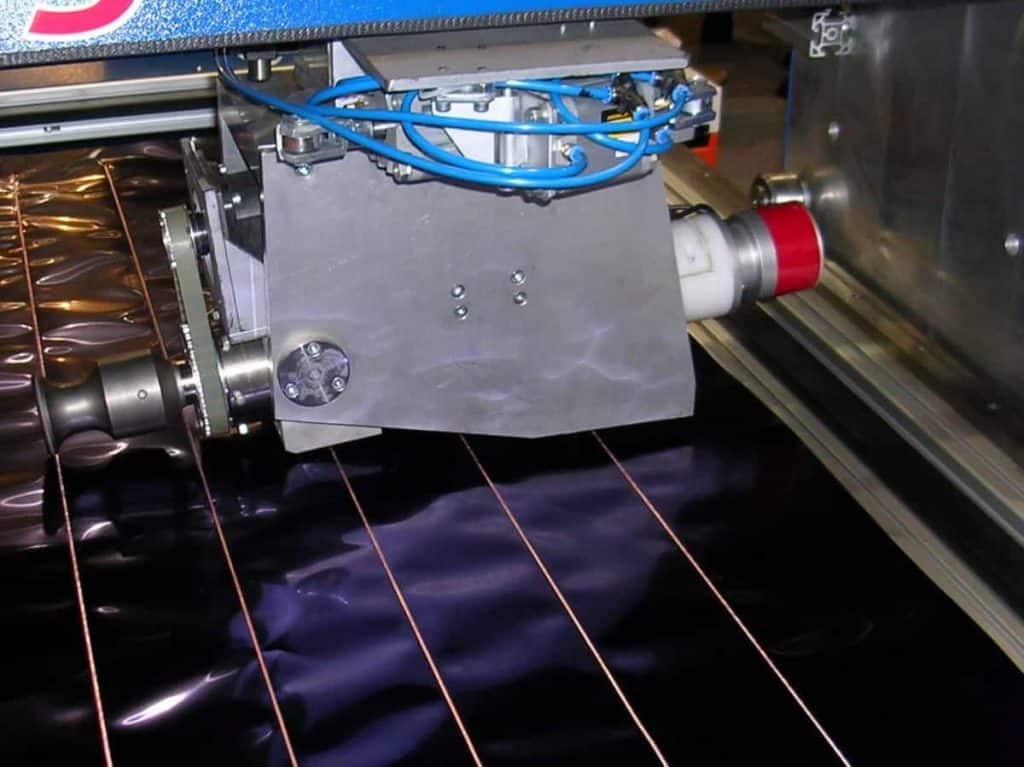

Also known as a sonotrode, the horn is a connection between materials to be welded and the ultrasonic welding machine. The ultrasonic vibrations are targeted to a specific level. Generally, the materials to be welded are set on anvil or other sorts of structures that keep them together. The machine also connects to a pneumatic press so that the horn can pass the strain to the components.

Although the ultrasonic welding technique may involve some other items, the parts mentioned are the ones commonly used to perform the welding process. It is helpful to understand the role of the different components of the ultrasonic welding machine and how they work. This will help to expedite the process.

What are the Advantages of Ultrasonic Welding?

With the rapid speed of welding, high welding strength, and excellent sealing efficiency, the ultrasonic welding technology stands out. It is an effective substitute for conventional welding/binding methods. The method is safe because it does not use toxic chemicals or adhesives. It does not cause any damage to the product either. Additionally, this technology is easy to incorporate in the manufacturing process and has a low failure rate. All of these benefits can help reduce the cost of production.

What Is The Difference Between Ultrasonic Welding And Vibration Welding?

Often people mistake vibration welding for ultrasonic welding and vice versa. This is because both methods utilize vibrational force to weld plastic assemblies. However, the reality is that both these welding techniques are very different from each other.

The vibration welding method pulsates in a linear side-to-side movement with one part proportional to another. The friction between the two parts produces the heat, which is used to perform the weld. In comparison, the ultrasonic welding method pulsates one part parallel to another, just like a jackhammer or pavement.

What Materials Can Be Ultrasonically Welded?

Ultrasonic welding has a range of applications. These include (but are not limited to) mounting of lenses and windows in housings, plastic-to-plastic joints, and placement of mechanical clamps, studs, and pierced inserts into molded components for plastic injection. Is your item a suitable ultrasonic welding candidate? If it is, then using this welding method has many benefits, as opposed to conventional welding. These include the following:

Cold Welding Tools

As this method uses ultrasonic vibrations, there is no wait time for equipment to power up or warm the products that are being welded.

Water-Tight Welds

Ultrasonic welds are perfect for binding. This is because the weld themselves are both airtight and watertight, for example, in packaging.

Eco-Friendly

Usage of an ultrasonic welder needs less energy than a conventional weld. Therefore, there is no wastage from fillers or additives.

Final Thoughts

By now, we know what ultrasonic welding is, the process used to perform it, how ultrasonic bonding works, the different parts involved in this welding technique, and the advantages of the ultrasonic process. With this information, you can find out if ultrasonic welding is appropriate for your specific application and also how you can perform it efficiently to get the best results.